In his last post of May 17th Why Organizations Struggle with Customer Experience @joseph.colletti said,

Taking a page out of W. Edwards Deming’s approach to quality management, we must consider the “people” definition as not only the actions of individual employees, but also the organizational structure.

I took notice of this because it's rare to get anyone quoting Deming when they're talking about customer experience and especially about customer satisfaction. Edwards Deming, and his resultant TQM and Six Sigma methodologies have been relegated to the ranks of engineers. And Deming is just some guy who went to Japan in the 80's and helped the car companies improve their product quality.

But he also said this:

If you can't describe what you are doing as a process, you don't know what you're doing.

That's what Six Sigma was all about. And the processes he was referring to included services:

Improve constantly and forever the system of production and service, to improve quality and productivity,

and thus constantly decrease costs.

Six Sigma and good old-fashioned statistical process control (SPC)

SPC is the tried and true method that engineers used to monitor processes of production. It's the basis for product quality control, and a key technique in Six Sigma. Engineers set control limits, and follow rules that dictate when a process is "in control". Anomalies, the so-called "signals in the noise" occur when the measurements break certain rules, and are thus deemed "out of control". In fact, the 6-Sigma moniker was coined from the notion that a process under control mainly stays within a 6 sigma range - 3 sigma above the mean; 3 sigma below the mean.

The key thing is, you need to have process measurements in place. Which is natural in production processes. They are very measurement oriented. But why don't we apply Six Sigma to customer experience? Is just a culture difference thing? Customer experience / customer service people tend to be less likely to use process engineering techniques. The two don’t’ seem to mix.

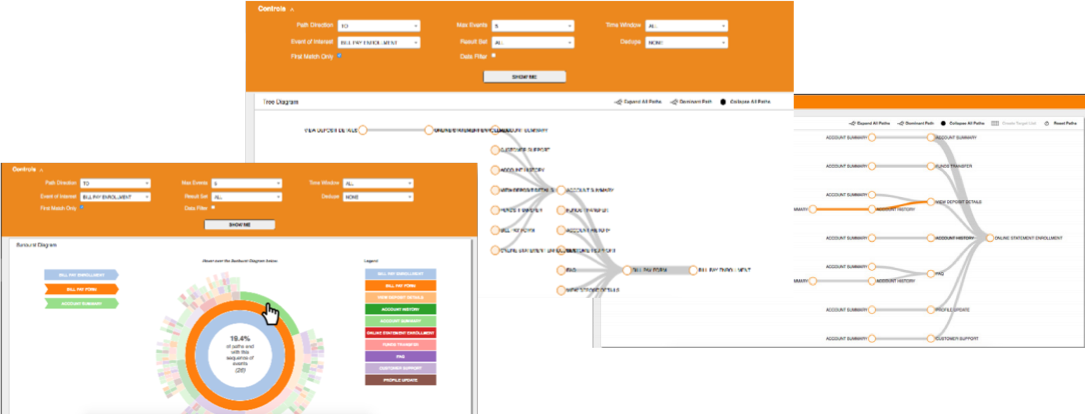

But it would be applicable: we could model the pathways (or journeys) that customers take through our processes. We could measure them, monitor them, and then use the measures (both quantitative and qualitative) to run experiments to see what triggers a response. Where the response variable is customer satisfaction, or Net Promoter Score.

Measuring Customer Processes

How do we turn customer process data into something to which you could apply Six Sigma? Two examples come to mind:

1. Measuring deviations from golden path

Let's say you want to reduce friction in the process of getting your customer to a certain state. You may have previously studied and determined what the “golden path” is, the ideal, least friction way to get your customers to engage and buy: golden Path to Purchase. You could then put measures around the likelihood and experience customers might experience lower satisfaction by not following that path. Alternatively, let's say you wanted to understand the reasons you customer defects, or churns. You would study the Pathways to Churn, and similarly alert on how often, and what leads to customer following that path.

2. Measuring cycle time variation

Another way to measure customer processes is to set quantitative standards, such as cycle time, or service levels, and measure the achievement of these. Then the variance to the standard can be measured and tracked. Process variation is a powerful quality measure, and outliers can signal problems.

3. Measuring Customer Experience Response:

Entire books have been written on how to measure customer delight. Back in the early 00's Apple actually came up with Net Promotor Score (NPS). This is very easy to measure, understand and implement.

Six Sigma / SPC for Customer Experience

Ok, so we have a couple of ways to measure the process itself. We have a popular and well-defined way to measure customer satisfaction, via NPS. Then the key is to treat the process measures as independent variables, and the NPS as the response variable. We have the makings of Six Sigma for Customer Experience!

Now we have that framework for conducting experiments and seeing their response in NPS. I would submit that this basic, back-to-Deming idea could be successfully applied to customer experience, and rolled out to the entire enterprise for a unified way to measure the effects of our efforts to improve them!

In future posts, I'll talk more specifically about process engineering for other types of processes, for example:

- New product issues

- Customer complaints

- ePayments Fraud

- Incoming supplier quality

Cheryl Wiebe is an Ecosystem Architect in Teradata’s Data and Analytics Strategy team in the Americas region, and works from her virtual office in Southern California. Her focus is on the business, data, and applications areas of analytic ecosystems. She has spent years working with customers to help create a digital strategy in which they can bring together sensor data and other machine interaction data, connect it with other enterprise and operational domain data for the betterment of the reliability and efficiency of large equipment, large machinery, and other large (and expensive) assets, as well as the supply chain and extended value chain processes around those assets.

Industry-spanning programs, such as Industry 4.0 and others that address enterprises in their goals to “go digital” in a journey to the cloud, are where Cheryl focuses. She helps companies leverage traditional and new IoT settings to organize and develop their business, data and analytic architectures. This prepares them to build analytics that can inform the digital enterprise, whether it’s in Connected Vehicle services, Smart Mobility, Connected Factories, and Connected Supply Chain, or specialized solutions such as Industrial Inspection / Vision AI solutions that address needs to replace tedious work with AI.

Cheryl’s background in Supply Chain, Manufacturing and Industrial Methods stem from her 12+years in management consulting, industrial/high tech, analytics companies, and Teradata, where she’s spent the last 18 years.

View all posts by Cheryl Wiebe